PRODUCT CENTER

WHAT WE OFFER

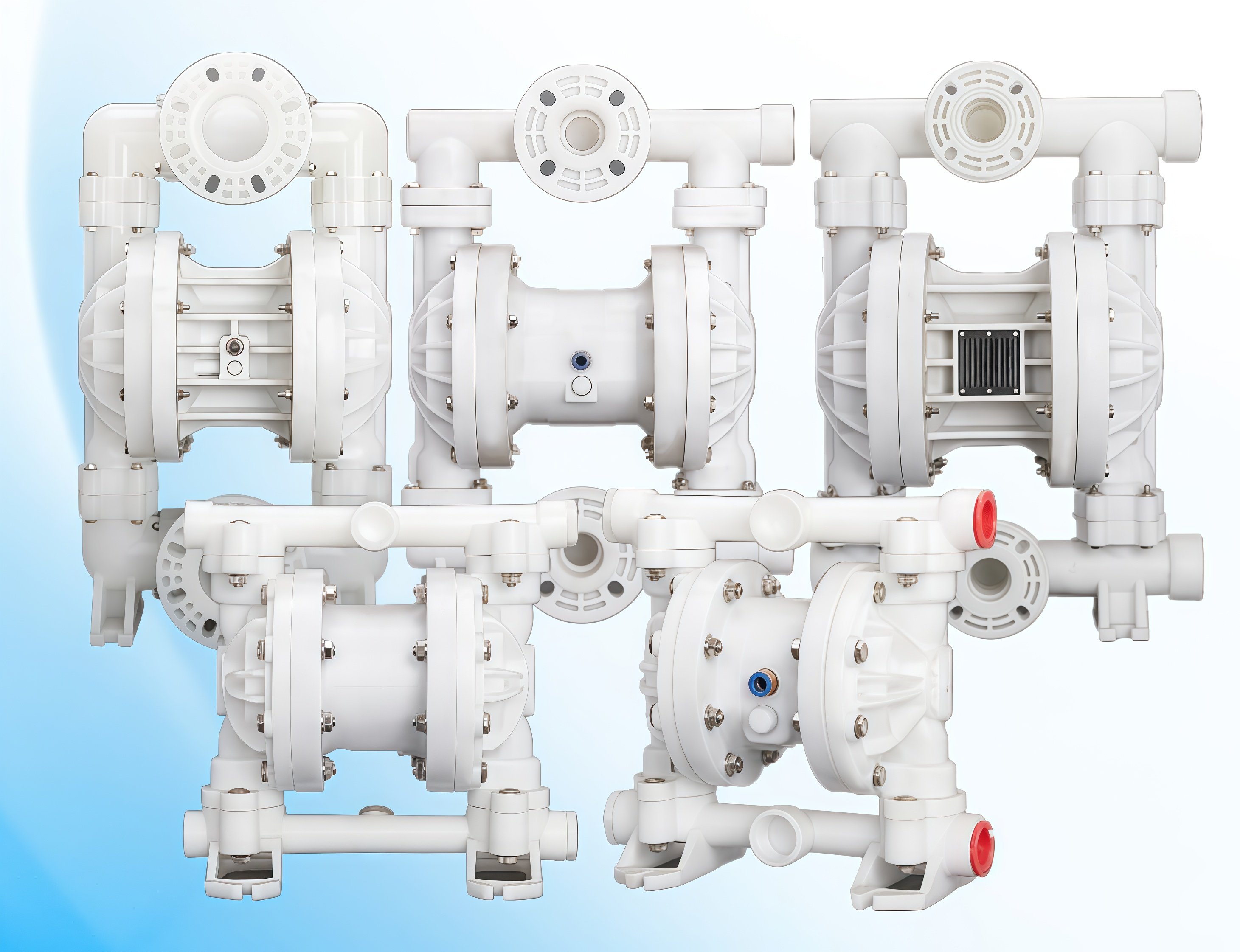

CSJuQiao , Manufacturing Vavle Series

Maximum particle diameter [mm] 2

Inhalation and discharge outlet [in] 1

Compressed air inlet [in] 10

Maximum flow rate [m ³/h] 3.5

Maximum head [m] 70

Maximum air supply pressure [bar] 7

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-10.0 MPa

3.Flow capacity: 0-86400 m3/h

4.Technical characteristics:

①Submerged layout

②Excellent anti-cavitation performance3. Large decompression ratio of 20:1

③The linear adjustment

④Flow adjustment and pressure adjustment

⑤High-precision adjustment valves

5. Driving mode: manual,electrical, hydraulic

6. Typical applications: Pressure of pipeline. Accurate adjustment and control of flow. Discharge of the dam. Ecological discharge control of bypass unit.

1.Nominal diameter: 300-2000 mm

2.Nominal pressure: 2.5-10MPa

3.Technical characteristics:

①Electrical and hydraulic pressure all in one.

②Switching on by hydraulic and switching off by heavy hammer. Safe and reliable.

③Hydraulic driving. Double-metal sealing.

④Compact structure for saving space.

⑤Meet the requirements of "Unattended, Few people attended".

4.Driving mode: Hydraulic.

5.Typical applications: Turbine inlet valve.

1.Nominal diameter: 100-3000 mm.

2.Nominal pressure: 0.6-2.5MPa.

3.Technical characteristics:

①Simple in structure and weighs light. Flexible for opening and closing.

②Eccentric structure for reducing the friction of sealing ring.

③Reasonable design of sealing structure.

④Apply to different medium and temperature.

⑤Vertical or horizontal installation.

⑥Easy assembly and disassembly, convenient for maintenance.

4.Driving mode: manual, electrical.

5.Typical applications: Water and water resource projects; Environmental protection; Municipal facilities; Electricity and utilities; Construction industry, Petrochemical industry; Iron and steel metallurgy; Paper industry.

Founded in 2005

Shijiazhuang Kaiquan Slurry Pump Co., Ltd.

Shijiazhuang Kaiquan Slurry Pump Co., Ltd. was established in 2005 with the total investment of 20 million USD, covering total area of 47,000 square meters & building area of around 22,000 square meters. At present, it has 250 experts, senior engineering technicians and skilled workers. There are the world advanced resin production line and the continuous sand mixers. All casts adopt phenol sand molding and it has 2-ton & 1-ton medium frequency furnaces which can cast 8-ton single alloy pieces. In addition, it has more than 300 sets of advanced equipment.

PARTNER

ABOUT US

JUQIAO TECHO(CHANGSHA) CO LTD

JUQIAO TECHO(CHANGSHA) CO LTD is a manufacturing enterprise specializing in the production,design, research and development, sales and service of valves , pumps, accessories and large construction machinery parts. There are many production bases in our country, the headquarters is located in Changsha, Hunan. With more than 60,000 square meters of modern factories and office buildings, there is a professional technical team, sophisticated technology, perfect testing, to ensure that every product qualified. Our Valves include Industrial Valve Series, Anticorrosive Valve Series, Self-operated Regulator Series and Water Supply & Drainage Valve Series. The products are widely used in the domestic and internationall large and medium key projects of construction fire protection, petrochemical, new energy, bio-pharmaceuticals, papermaking, light textile, water diversion, water supply, hydropower, thermal power, metallurgy, heating supply, irrigation, etc.. JUQIAO Valve, your ONE-STOP Product Customiztion & Engineering Solution Provider.

Product production line

Our company have an area of 60000㎡

Exporting countries and regions

Video

We are eager to collaborate with you and welcome you to visit our production factory

Our valves include industrial universal valves, desulfurization and denitrification, anti-corrosion valves, self regulating valves, water supply and drainage valves, flange standard valves, food hygiene grade valves, and support the production of different materials, including check valves, gate valves, globe valves, butterfly valves, and ball valves. They are suitable for various aspects of life and have been widely used in industrial manufacturing, agricultural irrigation, petrochemicals, water plants, sewage treatment, natural gas and other fields. We have deep cooperation with many well-known Chinese enterprises and have accumulated a large number of loyal customers.

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

WHY CHOOSE WE

To help solve production problem and enhance company competitivenessis our eternal persuit.

2025

05-01